Introduction Of Utility Channel Strut Fittings

Utility channel strut fittings are the unsung heroes of infrastructure and construction projects, providing structural support and adaptability to various applications. These versatile fittings, designed to work seamlessly with channel struts, play a pivotal role in creating sturdy frameworks for electrical, mechanical, and plumbing systems. In this article, we will explore the world of utility channel strut fittings, their diverse features, and how they contribute to the success of your projects.

Understanding Utility Channel Strut Fittings

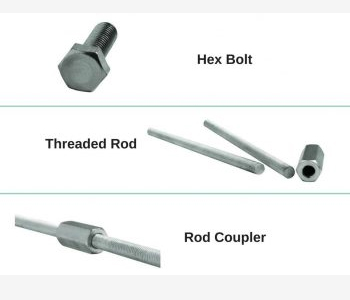

Utility channel strut fittings are specialized components used in conjunction with metal channel struts, typically made of steel or aluminum. They are engineered to create secure and adaptable frameworks for various utility systems. These fittings come in a wide range of shapes and sizes, allowing for endless configurations and applications.

Features and Benefits Of Utility Channel Strut Fittings

Versatility

Utility channel strut fittings are compatible with a variety of systems, including electrical, mechanical, and plumbing installations. They can be easily customized to meet specific requirements.

Durable Materials

Made from robust materials like steel, stainless steel, and aluminium, these fittings are designed to withstand heavy loads, environmental stress, and corrosion.

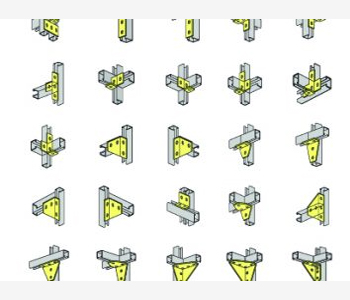

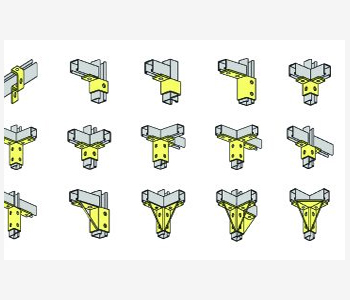

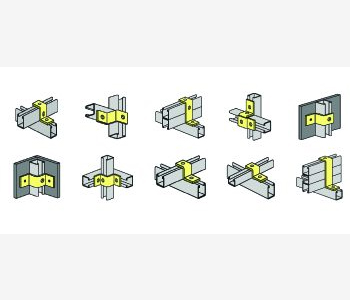

Modular Design

The modular design allows for easy assembly and flexibility. Strut fittings can be easily adjusted, expanded, or reconfigured as needs change, without requiring extensive modifications.

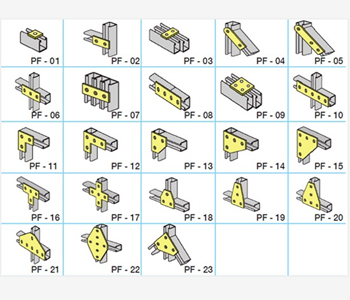

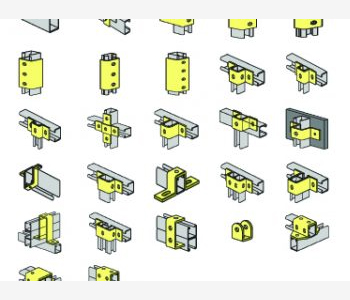

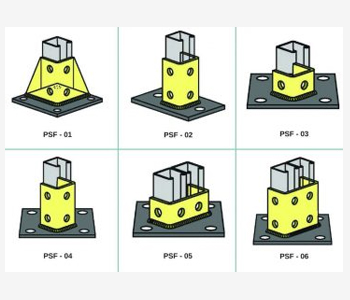

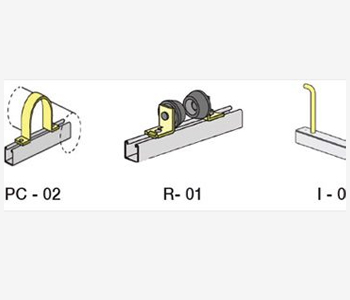

Variety of Types

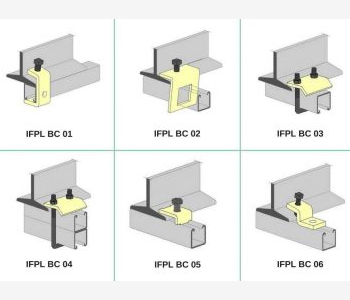

These fittings come in a wide range of types, including elbows, tees, brackets, clamps, and more, ensuring compatibility with different configurations.

Corrosion Resistance

Many utility channel strut fittings are coated or made from corrosion-resistant materials, ensuring they remain reliable in harsh environments, such as outdoor, industrial, or marine applications.

Ease of Installation

These fittings are designed for quick and easy installation, saving time and labor costs. They often require fewer tools and no welding, which streamlines the installation process.

Adjustable and Reconfigurable

The modular nature of the system means that adjustments and expansions can be made without the need for major alterations, ensuring long-term flexibility.

Common Cable Tray Accessories

- Cable Tray Covers Protect cables from dust, moisture, and physical damage, while also enhancing safety by preventing contact with live wires.

- Cable Tray Dividers : Organize and separate cables within the tray, preventing cross-interference and making it easier to identify and trace specific cables.

- Splice Plates : Used to join and connect cable trays, ensuring a secure and reliable connection between sections.

- Cable Tray Mounting Brackets: Secure cable trays to walls, ceilings, or floors, providing stability and structural support.

- Cable Tray End Caps : Seal the ends of cable trays to prevent cable spillage and protect against potential hazards.

- Grounding Kits : Ensure proper grounding of cable trays, reducing the risk of electrical faults and ensuring electrical safety.

Applications of Utility Channel Strut Fittings

Electrical Installations

Used for supporting and organizing electrical cables and power distribution systems.

Mechanical Systems

Supports HVAC ducts, pipes, and ventilation systems in commercial and industrial environments.

Plumbing Installations

Provides secure routing and support for plumbing pipes in various systems.

Industrial and Manufacturing Environments

Supports machinery, tools, and conveyor systems in factories and warehouses.

Commercial and Residential Construction

Creates frameworks for electrical, plumbing, and mechanical systems in buildings.

Telecommunications

Supports cables, antennas, and equipment in telecom facilities and data centers.

Conclusion

- Utility channel strut fittings are integral to creating strong, flexible, and organized support systems in construction and infrastructure projects. Their versatility, ease of use, and durability make them a valuable addition.